conversions for rockwell b hardness test for cylindrical samples|rockwell b50 to tensile strength : trade Find the roundness correction factors for Rockwell testing and Rockwell superficial testing here. Download as PDF or get the roundness corrections right away. WEB20 de dez. de 2023 · FTS 24 SUL-AMERICANO MOD PES BRAZUKAS ATUALIZADO COM BRASILEIRÃO A,B,C E NARRAÇÃO BRASILEIRA. Carlitos FUT. 11.8K subscribers. Subscribed. Like. Share. 1.2K views 13 days ago #FTS24ATUALIZADO.

{plog:ftitle_list}

WEB27 de dez. de 2023 · Servidor Avançado Free Fire: Download APK 66.35.0 Advance FF (link direto) Jogadores já podem baixar o APK do Servidor Avançado com a nova .

If a Rockwell test is conducted on cylindrical parts, then, due to the lower resistance of the test surface with respect to the indenter, the following correction values – depending on the .

When testing cylindrical specimens, the accuracy of the test will be seriously affected by alignment of elevating screw, Vee-anvil, indenters, surface finish, and the straightness of the .Find the roundness correction factors for Rockwell testing and Rockwell superficial testing here. Download as PDF or get the roundness corrections right away.Corrections to be added to Rockwell C, A, and D values. When testing cylindrical specimens, the accuracy of the test will be seriously affected by alignment of elevating screw, Vee-anvil, . Most designers try to convert their hardness testing scales to more suitable ones like Rockwell hardness B and C scales. This article compares two types of Rockwell .

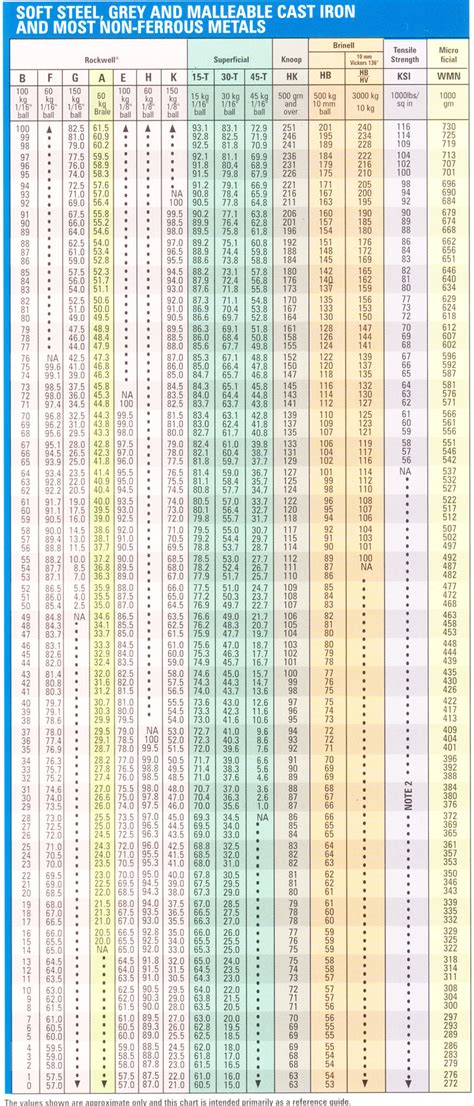

ASTM E140 — ROCKWELL B RANGE (NON-AUSTENITIC STEELS) These values are approximate and this chart is intended primarily as a guide.

The Rockwell hardness conversion calculator is the tool when you are looking to calculate or convert the hardness numbers across various scales. The hardness tests help evaluate a material's resistance to plastic .Hardness Conversion-ASTM_10-20-1. | Hardness Conversion Chart. Hardened Steel and Hardened Alloys Cylindrical Correction Chart 53. Cylindrical work corrections to be added to .

Loop Tack Tester

rockwell scale conversion chart

This part of ISO 6508 specifies the method for Rockwell regular and Rockwell superficial hardness tests (scales and applicable range of application according to Table 1) for metallic .Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers .10 Conversions to other hardness scales or tensile strength values . convex cylindrical surfaces . ISO 6508-3:2015, Metallic materials — Rockwell hardness test — Part 3: Calibration of reference blocks 3 Principle An indenter of specified size, shape, and material is forced into the surface of a test specimen under two .Visit Brystar Tools for Technical Resources for Hardness Testing. Categories Categories Brands Brands. Additional Information . How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness .

Versitron Rockwell Hardness Tester Upgrades; Microhardness Tester Upgrades; LEARNING ZONE. Guides to Hardness Testing. Hardness Conversion for Rockwell C Scale or High Hardness Range; Hardness Conversion for Rockwell B Scale or Low Hardness Range; Minimum Thickness Requirements Guide; Roundness Correction Factors; Rockwell . Cylindrical Testing and Correction Factors. . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality control and acceptance, and performance of materials. . Sample Holders .

The Rockwell Measuring Principle The test principle of the Equotip Portable Rockwell follows the traditional Rockwell static test method. During measurements with the Equotip Portable Rockwell Probe, a diamond indenter is forced into the test piece using a precisely controlled force. The indentation depth of the diamond is continuouslyTable 1 — Rockwell scales Rockwell hardness scale Hardness symbol Type of indenter Preliminary test force F 0 Additional test force F 1 Total test force F Field of application (Rockwell hardness test) Aa HRA Diamond cone 98,07 N 490,3 N 588,4 N 20 HRA to 88 HRA Bb HRB Ball 1,587 5 mm 98,07 N 882,6 N 980,7 N 20 HRB to 100 HRB

The hardness of steel depends on several factors, such as its composition, manufacturing, and heat-treating processes.The different hardness scales use different loads, different indentor shapes, and different measurements to obtain the hardness number. There are no straightforward formulae to establish relationships between the different scales, making .The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on . samples to a laboratory or for situations that require imme-diate hardness assessment. Portable Testing 1.1. Rockwell Methods

Hardness, as applied to most materials, plus by particular metallized, a a valuable, disclosing, and commonly worked mechanical test that has are in use in. Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in.SC 3, Hardness testing. This fourth edition cancels and replaces the third edition (ISO 6508-1:2015), of which it constitutes a minor revision in order to clarify the scope of this part of ISO 6508. ISO508 6 consists of the following parts, under the general title Metallic materials — Rockwell hardness test: — Part 1: Test methodRockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Transcribed Image Text: There are two samples, A and B, ere tested by Rockwell hardness test. Sample A is tested in B scale, shows hardness value 59 HRB. Sample B is tested in F scale, shows hardness value 90.5 HRF. Which sample is harder? OL. Sample B O II. No way to compare sample A and B. O II. Sample A and B are same. OIV. Sample ASteel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength.Specifically, conversion charts from Rockwell hardness to tensile strength are available for some structural alloys, including steel and aluminum. . (150 mm) thick or larger can be accommodated. The minimum sample size depends on the sample hardness and test scale. Cylindrical samples as small as 1/8 in. (3 mm) in diameter, and thin sheets 0. . The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting .

When testing on cylindrical surfaces the results will usually show a lower hardness value than if the material was flat. . Verification should be performed by an accredited verifying agency and the report should follow and reference ASTM E18 Rockwell test method. Hardness testing is an important and useful tool in materials testing, quality .To apply the correction coefficient on cylindrical or spherical samples, it is essential to verify that the minimum diameter/radius is respected with reference to the Rockwell hardness test scale chosen. For your convenience we have .How To Operate The Analog Rockwell Hardness Tester ; Cylindrical Correction Chart; Hardness Conversion Chart - Rockwell "B" Hardness Range . Hardness Conversion Chart - Rockwell "B" Hardness Range. Newsletter signup. Name; Email; Further info. . Rockwell Test Blocks; Brinell Test Blocks; Covers; Jack-Rest Stands; Cabinet Stands;

Specifically, conversion charts from Rockwell hardness to tensile strength are available for some structural alloys, including steel and aluminum. . (150 mm) thick or larger can be accommodated. The minimum sample size depends on the sample hardness and test scale. Cylindrical samples as small as 1/8 in. (3 mm) in diameter, and thin sheets 0. . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings.There are two general classes of Rockwell test: Rockwell and superficial Rockwell. In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf. In superficial Rockwell testing, the minor load is 3 kgf and major load is 15, 30 or 45 kgf. In both types of test the

There are two general classes of Rockwell test: Rockwell and superficial Rockwell. In Rockwell testing, the minor load is 10 kgf and the major load is 60, 100 or 150 kgf. In superficial Rockwell testing, the minor load is 3 kgf and major load is 15, 30 or 45 kgf. In both types of test theThe scope of use of every test is different but the most common method is Rockwell. The Rockwell hardness B scale is used for soft or mild metal materials. + 86 755 61301520; . The Rockwell hardness test measures the eternal depth created by a specific indenter and a specific test force. . Importance of Hardness Conversion: Rockwell .Rockwell Hardness Testing System. . from test samples shifting under load. I. ntuitive Touch Screen Operation . AT/5313 Wide Vee Anvil For testing cylindrical specimens. AT/5318 Set of 3 Small Anvils For small parts testing. Includes flat, spot, and round anvils and anvil adapter.Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales). High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing

Plastic Film Tester

ASTM E18 contains a listing of all regular Rockwell scales and typical materials for which these scales are applicable. Use these tables in selecting the scale that is appropriate for your application.

When testing cylindrical specimens, the accuracy of the test will be seriously affected by alignment of elevating screw, Vee-anvil, indenters, surface finish, and the straightness of the cylinder. These corrections are approximate only and represent the averages, to the nearest 0.5.

rockwell hardness scale comparison chart

Mechanical Pendulum Impact Tester

rockwell b50 to tensile strength

Comprar episódio 1 em HD por US$ 2,99. Comprar temporada 2 em HD por US$ 19,99. Mais opções de compra/aluguel. Lista. Curtir. Não tenho interesse. . Co-creators Dan .

conversions for rockwell b hardness test for cylindrical samples|rockwell b50 to tensile strength